Improving Aggregate Crushing Efficiency- …

Crusher in order to improve crusher efficiency in this way the very coarse portion is crushed and then recombined with the portion of crusherrun material before further processing this first step may however be an excellent time to improve a deleterious problem if a deleterious or fines. More Details An Investment In Next Generation Crushing Technology . Aug 16 2017 an investment in next ...

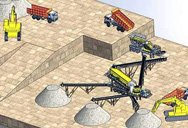

Tips to maximize crushing efficiency - Pit & …

Tips to maximize crushing efficiency. By Edited by Kevin Yanik | May 13, 2019. Crushing efficiency is key to production. Photo by Kevin Yanik. Efficiency can be defined by the ratio of a machine’s work to the energy supplied to the machine. To apply what this means to your crusher, operations produce the exact sizes in the reduction process that their market demands. In the past, quarries ...

How to improve the Working Efficiency of Jaw …

How to improve the working efficiency and reduce the failure rate of jaw crusher is very important. In terms of equipment operation and maintenance, operators should do a good stone in the normal inspection; for operators, to strengthen the operators equipment training, to help operators understand and master the operation skill. Below, we focus on the daily maintenance and operation that need to pay attention.

5 tips for energy efficient and productive cone …

If the crusher lube oil pump is not properly maintained and the flow rate decreases due to internal pump wear, circulating lube oil temperature will increase. The increase in crusher drain oil temperature will cause the oil cooler fan motor to cycle on and off more frequently throughout the day or in worst case scenario, to run continuously. This inefficient use of connected horsepower will result in a …

how to improve efficiency of primary crushers

improve crusher efficiency How should we do to improve cone crusher efficiency in crushing Jul 6, 2015 Check the following things 1. More Calculating the efficiency of impact crushers for, research, development, designs calculating the efficiency of impact crushers for bulk materials e v semenov and l a glebov udc 6219264.

Improve Crusher Efficiency - plaidwebshop.nl

Crusher Efficiency Improvecrusher Efficiency Industry. Crushing efficiency crusher mills, cone crusher, new crushers improve pyrite crushing efficiency. the holidays how to have more joy, less stress. create more joy and trim your waist size during the holiday season. more how to improve efficiency of a jaw crusher improve crusher efficiency jaw crusher, raymond mill . pe jaw crusher.

Crusher Efficiency Improvecrusher Efficiency …

How To Improve The Efficiency Of Cone Crusher. Improve crusher efficiency kasprzykarteu. improve crusher efficiency educationcare crusher a crusher is a machine designed to reduce large rocks into smaller rocks, gravel allows smaller material to bypass the crusher itself, thus improving efficiency. hammer crusher to improve the bauxite crushing efficiency

Crushing Efficiency Factors - 911metallurgist.com

Crushing Efficiency Factors. Previous Next. View Larger Image . Toward the foregoing goal, engineers investigated the energy efficiency of crushing for less than ideal cases. In the first experiment they studied the effect of factors such as using a deep bed of particles, a situation usually present in a ball mill. The same type of slow crushing experiment described above was performed, but ...

Crusher Efficiency Calculations

A better solution would be to use a larger jaw crusher set at 1½ in., then a roll crusher from the Roll Crusher capacity Table above could be used. If the output of this crushing process should have less material of the +1-in. size, the larger crusher could be operated with a closed circuit. That is, the oversize in the output could be recirculated through the roll crusher without exceeding the …

how to improve efficiency of primary crushers

how does the jaw crusher archives efficiency. PE series jaw crusher is usually used as primary crusher in quarryproduction lines, , increase efficiency of stone crusher screen - mine-equipments. Live Chat; How to improve impact crusher efficiency in crushing , How to improve impact crusher efficiency in crushing , we can select suitable primary ...

Crusher regular maintenance to improve efficiency

Crusher regular maintenance to improve efficiency he material of crusher plays an important role in its working efficiency and service life However the regular operation and maintenance are important too During the using process if the worker operates and maintains the crusher according to correct standards it will have great significance in normal production output quality service . Read More ...

Crusher - Wikipedia

A feeder device such as an apron feeder, conveyor or vibrating grid controls the rate at which this material enters the crusher, and often contains a preliminary screening device which allows smaller material to bypass the crusher itself, thus improving efficiency. Primary crushing reduces the large pieces to a size which can be handled by the downstream machinery.

efficiency crusher improve - …

How to increase efficiency crusher plant. Improve Work Efficiency of Stone Crusher 1 Materials should distributed as evenly as possible in order to reduce the impact and wear to the crushing parts 2 Controlling the particle size position of the material The more fine material content in material the lower working efficiency of the crusher

Improve Efficiency Of Impact Crusher

Improve Efficiency Of Impact Crusher What is the production efficiency of the impact crusher that is not expected Many users want to know how much the impact crusher is Users can know the counterbreaking model and parameters in advance and then ask the manufacturer of the countercrusher after selecting the model. Email: [email protected] Get a Quote Send Message. Products Show …

Formula Of Crushing Efficiency Crusher Usa

Formula Of Crushing Efficiency Crusher Usa. Crusher Efficiency Calculations. A jaw crusher, like 2036 in the Jaw Crusher Table here above, would be able to take the maximum 12 in. size quarry stone but it would not have the required 70 tph capacity needed. To have the needed capacity a jaw crusher like the 2042 or 2436 sizes will have to be selected overloading the secondary crusher. Get a ...

Increase Efficiency Of Stone Crusher Screen

Crusher Efficiency Improve Lekkeretenzonder. Crusher efficiency test 1 fill box level with discharge material from crusher 2 dump contents onto like-sized screen cloth as the crusher discharges to 3 work material around by hand and place the oversize back into the boxf the box is 13 full, for example, the crusher is operating at 65 percent efficiency.