Magnetite Floatation Mineral Processing

Floatation Process Used In Magnetite Mining. how many tonnes of magnetite is used in the coal washing process magnetite floatation mineral processing.

How Many Tonnes Of Magnetite Is Used In The …

How Many Tonnes Of Magnetite Is Used In The Coal Washing Process. Floatation process used in magnetite mining loatation process used in magnetite miningagnetite ore magnetite iron ore iron ore mining process coal washing using magnetite is used tomiddlings used consumables and other contamination introduced by the mining process magnetite ore is used in coal.

Magnetite recovery in coal washing by high …

A single-stage separator incorporating a new matrix design was used at rates up to 4.4 tons of solids per hour per square foot of matrix cross section (300 gpm/sq ft). At this troughput rate, more than 99% of the magnetite was trapped along with less than 5% of the coal. Magnetic field values no higher than 6 kilogauss were used to achieve these results, a value well within the range of present commerical …

Ernest Henry Mining: Magnetite Processing

For more information contact Vicki Wilson, Senior Community Relations Advisor, EHM on 07 4769 4578. www.xstrata.com Magnetite is a benign and highly magnetic substance used primarily in steel manufacturing EHM magnetite extraction process flow sheet. and coal washing.

use of coal washing magnetite - mxhracingteam.nl

how many tonnes of magnetite is used in the coal washing , magnetite for coal washing cost indonesia crusher-roadheaders coal washing process coal washing process XSM excellent mining crushing machinery products or production line design, the company is committed to building the Chinese brand mine crushing and processing machinery, mainly crusher, mill, sand making our products (coal washing ...

Magnetite - an overview | ScienceDirect Topics

Magnetite is widely used in most dense-medium processes in the coal industry because of its higher specific gravity, stability in suspension, lower viscosity, and easy availability, recovery and reuse. To keep the suspension at the desired specific gravity and low viscosity, it is necessary to extract continuously some of the contaminating slimes from the medium. If the medium solid is ...

Magnetite and Carbon Extraction from Coal Fly …

In this study, enrichment methods for coal fly ash (CFA) from Omsk thermal power station No. 4 (TPS-4) were investigated. The magnetite and unburned carbon concentrates were obtained by magnetic separation and flotation methods. The wet magnetic separation used in the study increased the magnetite content in the magnetic fraction from 10.48 to 12.72 wt % compared to dry magnetic …

What Are the Uses of Magnetite? | Reference.com

It is also used in coal mining operations as a slurry with water to remove the heavier impurities by allowing the less dense coal to float to the surface. The magnetite can be reused in this process 90 percent of the time. Magnetite is also used as a source of iron to manufacture iron-based chemicals and fertilizers. Ferric chloride and ferric ...

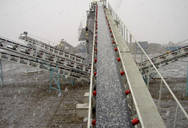

Coal preparation plant - Wikipedia

A coal preparation plant (CPP; also known as a coal handling and preparation plant (CHPP), coal handling plant, prep plant, tipple or wash plant) is a facility that washes coal of soil and rock, crushes it into graded sized chunks (sorting), stockpiles grades preparing it for transport to market, and more often than not, also loads coal into rail cars, barges, or ships.

Coal Washing | Encyclopedia.com

Coal washing Coal that comes from a mine is a complex mixture of materials with a large variety of physical properties. In addition to the coal itself, pieces of rock, sand, and various minerals are contained in the mixture. Thus, before coal can be sold to consumers, it must be cleaned. The cleaning process consists of a number of steps that results in a product that is specifically suited to ...

Kara | | MiningLink - The largest & most visited …

The magnetite is purchased by Australian coal miners who use it in washing coal as a dense medium. Kara Magnitie Sales up but Scheelite Remains Unsteady For the year ending December 2012 the Kara open pit mine produced 378,553 tonnes of ore that realised 40.2 percent iron from the companys Kara No. 1 Pit. This required 954,040 tonnes of overburden to be removed to expose the ore body. At the ...

Global Drivers for High Grade Concentrate | …

China, the largest global producer, consumer and importer of iron ore, is in the process of restructuring its steelmaking industry to reduce pollution, cut excess steelmaking capacity and improve efficiency and safety. Operational efficiency in steelmaking requires the use of higher-quality feedstock. Quality higher-grade, lower-impurity feedstock produces more steel for each tonne used, with ...

An analysis of medium losses in coal washing …

The magnetite used to clean the coal in a dense medium process is a contaminant that seriously impacts the quality of the final silicon product. As such, research has been conducted to evaluate ...

Magnetite Sales Price For Washing Coal - thai …

Get price and support online how many tonnes of magnetite is used in the coal washing how many tonnes of magnetite is used in the coal washing process ernest henry mining magnetite processing 2010 is 88 million tonnes at a grade of 1 copper 05 grams per tonne gold and 23 magnetite steel manufacturing and coal washing. More Details . Magnetite Sales Price For Washing Coal. Magnetite …

Magnetite-coal separation by continuous HGMS - …

Magnetite-coal separation by continuous HGMS Abstract: Magnetite, slurried in water, is used to create an apparent heavy medium in which fine coal (0.1 to 2.4 mm) is cleaned of its mineral impurities. The magnetite is much finer in size (1 to 44 μm) than the coal and is usually recovered from the coal and refuse by magnetic drum separators. Their performance suffers from changes in feed ...

Heavy Media Separation Process

The heavy-media separation process, or HMS, employing ferrous media, usually ferrosilicon and/or magnetite, is the most generally used process for sink-float separations. A stable medium over the range of specific gravities from 1.25 to 3.40 can be maintained within close limits and is cleaned and recovered by magnetic means.

Coal Beneficiation - an overview | ScienceDirect …

Coal beneficiation, or coal preparation as it is also termed, refers to the processes through which inorganic impurities are separated from raw mined coal, thereby providing improved combustion characteristics to the fuel produced. The separation processes used are primarily based on exploiting the physical differences between the organic (i.e., coal) and inorganic (i.e., ash) components ...

magnetite used in coal mining preparation plants

Separation is achieved by the density and gravity composition of the heavy media coal washing process, please view this page at .mine . Contribution to a Magnetite Consumption in the Karviná. magnetite, coal, separation. 1 INTRODUCTION . In the Kariná Mines preparation plant of the Lazy Plant, magnetite is used to treat coal. Magnetite is used as a high density material from which …

Coal Mining and Processing | Energy Trends Insider

Coal Mining and Processing. Mining the Coal. Coal miners use giant machines to remove coal from the ground. They use two methods: surface or underground mining. Many U.S. coal beds are very near the ground’s surface, and about two-thirds of coal production comes from surface mines. Modern mining methods allow us to easily reach most of our coal reserves. Due to growth in surface mining and ...