Gyratory Crushers - Mineral Processing & …

Gyratory Crushers. The primary rock breaker most commonly used in large plants is the gyratory crusher, of which a typical section is shown in Fig. 5. It consists essentially of a gyrating crushing head (521) working inside a crushing bowl (522) which is fixed to the frame (501).

Gyratory Crusher - an overview | ScienceDirect …

The gyratory crusher can, just like a jaw crusher, accept boulder sizes close to 1.5 m (for the largest equipment).. This crusher can handle products with a Mohs hardness that is not necessarily less than 5. – As is the case for jaw crushers, there is not any mutual sliding on grinding surfaces, but simply rolling of the nut on concaves.

Gyratory Crusher l Introduce, Working Principle - …

Gyratory crusher is a new type of crusher which can replace fine jaw crusher or cone crusher. The gyratory crushing equipment has a bright future in the mineral processing market. Its working part is a high-speed rotary crushing roller, which is coupled with a pair of curved crushing plates arranged symmetrically on the left and the right to form two optimal crushing cavities for the pliers ...

Crusher Advantages Salegyratory

Gyratory crusher - griffith, annesley - free patents online. this invention is concerned with gyratory crushers, as commonly employed for crushing rock or ore. ic invention relates to the type of gyratory crusher in which a vertical shaft mounted for gyra. News Particulars. High fine crusher . Fine crusher machinery the description and advantages of fine crusher fine crusher or highefficient ...

Gyratory Crushers Concerned - …

Gyratory Crushers Concerned; Gyratory Crushers Concerned battysbbq. Gyratory Crushers Mineral Processing & Metallurgy. Essentially, the gyratory crusher consists of a heavy castiron, or steel, frame which includes in its lower part an actuating mechanism (eccentric and driving gears), and in its upper part a coneshaped crushing chamber, lined

Crushing Equipment, Cone Crushers, Gyratory …

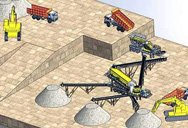

Cone crushers and gyratory crushers are mainly used as secondary crushers in a crushing plant. Crushed product from the primary crusher (usually Jaw Crusher) is fed through the top of the cone crusher and flows over the mantle. A vertical drive shaft rotates the mantle eccentrically below the bowl liner, squeezing the product and crushing it between the mantle and liner. View: 50; 100; All ...

Crushing technology | Technologies | Kleemann

Gyratory crushers differ from cone crushers with regard to their design. In contrast to the cone crusher, which has a fixed shaft on which the power supply unit and the head rotate, the gyratory crusher has a main shaft that can be moved hydraulically in vertical direction on which the head is permanently shrink-fitted.

liming CG800i GYRATORY CRUSHER SERIES

liming CG800i GYRATORY CRUSHER SERIES liming CG800i crushers are built to be robust, reliable and efficient. Connected to My liming, they revolutionize availability and optimize uptime by giving you actionable insights into how the crusher is performing. All to give you optimal reliability and drive down operating costs. CG800i crushers offer excellent reliability and safer & faster ...

Primary gyratory crushers - liming

limings product family of primary gyratory crushers is called Superior™ MKIII primary gyratory crushers. The “MKIII” stands for the third generation of the Superior™ primary gyratory crushers liming has developed during over 100 years in designing and manufacturing crushers.. The latest liming Superior™ MKIII primary gyratory crushers generation is again better, more efficient, safer ...

dict.cc Wörterbuch :: gyratory :: Englisch-Deutsch-Übersetzung

Englisch-Deutsch-Übersetzungen für gyratory im Online-Wörterbuch dict.cc (Deutschwörterbuch).

Crusher - Wikipedia

A gyratory crusher is one of the main types of primary crushers in a mine or ore processing plant. Gyratory crushers are designated in size either by the gape and mantle diameter or by the size of the receiving opening. Gyratory crushers can be used for primary or secondary crushing. The crushing action is caused by the closing of the gap between the mantle line (movable) mounted on the ...

CG830 Gyratory crusher — liming Mining and …

liming CG830i crusher is built to be robust, reliable and efficient. Connected to My liming, they revolutionize availability and optimize uptime by giving you actionable insights into how the crusher is performing. All to give you optimal reliability and drive down operating costs.

Compare Gyratory Crusher vs Jaw Crusher

Jaw and gyratory crushers are heavy equipment and are not used extensively in the stone industry. In a jaw crusher, the material is fed in between two heavy jaws, one fixed and the other reciprocating, so as to work the material down into a narrower and narrower space, crushing it as it goes. The gyrator crusher consists of a truncated conical casing, inside which a crushing head rotates ...

cone crusher concerned - Er zit muziek in logistiek

There are several types of crushers like Jaw Crusher, Gyratory crusher, impact crusher, cone crusher etc. About Cone crusher. As far as the functioning is concerned, a cone crusher is quite alike a gyratory crusher. Some of the distinct features of a cone crusher include its less steepness and specially characterized parallel zones amidst its ...

Gyratory Crusher Animation - YouTube

01.08.2016 · Dumping material into the gyratory crusher Luck Stones Bull Run Plant - Duration: 1:52. Aggregates Manager 47,727 views. 1:52. Gyratory Crusher Lube System - Duration: 2:05. ...

Crushers - All crusher types for your reduction …

liming has designed, engineered and manufactured crushers for more than 100 years. Our offering covers different jaw crushers, gyratory crushers, cone crushers, and impact crushers – optimized for any size reduction need. Jaw crushers. Efficient primary crushers. Gyratory crushers. High capacity primary crushers. Cone crushers. High uptime and consistent product quality in secondary, tertiary ...

Industrial Solutions Gyratory crushers

Industrial Solutions Gyratory crushers State-of-the-art technology with throughput rates of up to 14,000 t/h. Our solutions for the hardest stone Fields of application and design characteristics With crushing chambers of varying designs, these machines have either a high crushing ratio for preparing raw materials for secondary crushing or a low crushing ratio for reducing overburden for ...

Rock Crusher History - Mineral Processing & …

The gyratory principle was the basis of several rudimentary designs, patented between 1860 and 1878, none of which embodied practical mechanical details at least, not in the light of our present-day knowledge of the art. Then, in 1881, Philetus W. Gates was granted a patent on a machine which included in its design all of the essential features of the modern gyratory crusher.

Pebble Crusher Design Criteria

Gyratory crushers and cone crushers, while looking the same and performing The gyratory crusher is the older design, dating from the late 1870s. as quarries are concerned are in their size, pebble crusher design criteria sugarsmithcakes.co.za. pebble crusher design criteria. design criteria for crushers Hotsale Products: stone . cone crusher, impact crusher, mobile crusher for . >>Chat Online ...