Ball Mill Feeders - Mineral Processing & Metallurgy

The entire mill feed enters the drum via a chute or spout and an internal spiral carries the feed into the trunnion liner. The drum feeder may be used in lieu of a spout feeder when headroom limits direct spouting. The drum also provides a convenient method of adding grinding balls to a ball mill. The drum is generally lined with Manganese Steel.

mining ore feeding equipment for line ball mill - MECHINIC ...

We have mining ore feeding equipment for line ball mill,Ball Mill Machine. We provide ball mill equipment for cement plant, power plant, mining industry, metallurgy industry, etc. Ball mill can grind a wide range of materials, with enough continuous production capacity, simple maintenance. Capacity range from 5t/h to 210t/h. Thefeedingsize is less than or equal to 30mm.

Products / Feeding Equipment_ZK Ball Mill_Cement Mill ...

Henan Zhengzhou Mining Machinery Co. Ltd is one of the leading mining machinery manufacturer founded in 1956. Read More →

Ball Mill | Henan Deya Machinery Co., Ltd.

Ball Mill Introduction. Ball mill works on the principle of impact: size reduction is done by impact as the balls drop from near the top of the shell. A ball mill consists of a hollow cylindrical shell rotating about its axis. The axis of the shell may be either horizontal or at a …

feeding equipment for ball mill - cafe-zaalbergrust.nl

The dust-free cement raw material ball-milling device comprises a ball mill body, wherein a feed pipe orifice is arranged at one end of the ball... Ball Mill Scoop Feeder - YouTube Jan 2, 2014 ... crushing grinding screening equipment - Ball Mill and ...

Ball Mill|Feeding Machine For Ball Mill Price

Ball mill grinding machine is a kind of horizontal drumtype grinding mill with external gear and double bins materials goes evenly through quill shaft in feeding device into the first bin which has ladder lining or ripple lining with steel balls in different balls are taken to a certain height by centrifugal force from

Ball mills - liming

With more than 100 years of experience in ball mill technology, liming’s ball mills are designed for long life and minimum maintenance. They grind ores and other materials typically to 35 mesh or finer in a variety of applications, both in open or closed circuits.

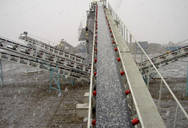

Feeding equipment | Henan Deya Machinery Co., Ltd.

Feeding Equipment. Henan Deya Machinery Co., Ltd. Feeding Equipment. Feeding Equipment admin2 September 25 ... 2008 certificate, and it has independent quality control department and after sale service department. Main equipment include Jaw Crusher, Ball Mill, Magnetic Separator, Flotation machine, Trommel Screen, Belt Conveyor, construction ...

Ball Mills - Mineral Processing & Metallurgy

Scoop Feeders for Ball-Rod Mills are made in various radius sizes. Standard scoops are made of cast iron and for the 3′ size a 13″ or 19″ feeder is supplied, for the 4′ size a 30″ or 36″, for the 5′ a 36″ or 42″, and for the 6′ a 42″ or 48″ feeder. Welded steel scoop feeders can, however, be supplied in any radius.

How to test the ball mill under the no-load test running ...

After the ball mill is idling for a specified time, you can stop the ball mill, carefully check all working parts, tighten the liner bolts, and eliminate the defects found. After there is no problem with the ball mill idling, the load test can be carried out. Load test run should be gradually added until full load.

Ball mill_The NIle Machinery Co.,Ltd

The ball mill is the key equipment for crushing the material after it is broken. Ball Mill is widely used in cement, silicate products, new building materials, refractories, fertilizers, black and non-ferrous metal mineral processing and glass ceramics and other production industries, all kinds of ores and other grinding materials for dry or wet-type grinding.

Feeding Equipment_ZK Ball Mill_Cement Mill_Rotary Kiln ...

Application: Feeding Equipment Apron feeder may be used as the material tank for feeding the primary crusher continuously and evenly, or used for conveying material with large granularity and gravity in a short distance. It may be installed flatly or tipsily, with the maximum tipsy angle of 12 degree.

Mining & Mineral Processing Equipment Manufacturer - JXSC

JXSC Mining Equipment for sale! Complete mineral processing equipment, rock crusher, gold wash plant, magnetic separator, magnetic separators, flotation machine, etc.

hengchangmachinery , Grinding Equipment

Wet pan mill also called gold round mill, it is versatile ore grinding equipment not only for grinding the minerals but also for gold amalgam. It is a best replacement for medium-small capacity ball mill, owing to the excellent performance for wet crushing, small investment and high output.

Feeding Equipment_ZK Ball Mill_Cement Mill_Rotary Kiln ...

It can evenly, continuously and quantificationally send the material with shape of block and stone form storage bin to the feeder. For instance, the feeding of belt conveyor, bucket elevator, sieving machines, crusher and grinder, and the automatic burdening and packaging, etc.

Jaw Crusher | Ball Mill | Rotary Kiln | Raymond Mill ...

Feeding size: 6-38mm. Wotetrack Jaw Crusher Station. Feeding size: ≤760mm. Processing capacity: Depending on the process ... Hongxings ball mill is of energy conservation and environment protection and efficiency of grinding. It is in stable work performance. ... Jaw crusher is the common mechanical equipment for processing the mineral ores ...

Buy Used Ball Mills - Used Mining & Processing Equipment

Buy Used Ball Mills. 52 Items Available Filter By Manufacturer. Sorty By 3 Units - UNUSED FLSMIDTH 26’ x 43 Dual Pinion Ball Mill with 2 ABB 9,000 kW (12,069 HP) Motors w/ ABB VFD for Total Power of 18,000 kW (24,138 HP) ... ELECTROWINNING CELLS [3] FEEDING EQUIPMENT [30] FILTERS [34] FLOTATION CELLS [20] GRINDING EQUIPMENT [171] HOISTS [16] ...

Energy Saving Ball mill,Ball grinder,Ball grinding mill ...

Ball mill grinding machine is a kind of horizontal drum-type grinding mill with external gear and double bins. Materials goes evenly through quill shaft in feeding device into the first bin, which has ladder lining or ripple lining with steel balls in different specifications.Steel balls are taken to a certain height by centrifugal force from drum rotation and then fall.