Silver processing | Britannica

Approximately 60 percent of all silver produced is used in the photographic industry, and the metal can be recycled from spent photographic processing solutions and photographic film. The solutions are processed on-site electrolytically, while film is burned and the ashes leached to extract the silver …

Silver Ore - The Mining Processes that Transform Ore into ...

Dec 18, 2016 · Silver Mining Process Silver is mined using a number of processes. One of the most common processes of extracting silver metal for the ore is the heap leach or cyanide process. The process is most popular with many miners because it is low cost, especially when processing …

Excellent Description of the Silver Mining Process ...

You probably know that silver is a metal that’s mined and then somehow refined to form the pure coins and bars we trade as bullion, but would you like to know a little more about that process? We’ve found an excellent little YouTube excerpt by the Discovery Channel on the process of mining and refining silver.

Silver Mining, Mines, Occurence, Techniques, Processing ...

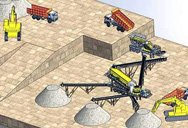

MINING AND PROCESSING : The Silver bearing ores are mined by either open-pit or underground mining methods after which they are crushed and ground. Despite of the existence of other technologies, this metal is mined through a process that uses gravity to break and extract its ores from large deposits.

Silver Mining and Refining | Education

Modern Silver Mining Even these ores are found in small quantities, and many tons of material must be mined to produce just a few ounces of silver. At least 80 percent of the world’s silver is produced instead as a by-product of mining for other metals such as gold, copper, lead, zinc, and uranium. Primary and secondary sources of silver ore.

How is Silver Mined | APMEX®

Silver also occurs alongside lead, copper and zinc ores, which is why nearly 50% of mined Silver today is obtained when processing other kinds of ore. Silver is separated from this ore using a stone process known as smelting. To begin a new Silver mine, a system of multi-layered crosscuts are made.

The Silver Extraction Process - athens123.com

Creating silver-bearing lead pigs by processing in a furnace . The bricks of washed Galena ore are being heated in a furnace to extract the lead containing a small proportion of silver. Noxious sulphur fumes are being emitted from the chimney. Sketch of smelter as we suppose it looked. Acknowledgements: The Lavrio Museum (panels)

What Is The Current Cost To Produce An Ounce Of Silver ...

For thousands of years, mining silver was not much different than mining copper or zinc or gold or iron. Past prospectors and exploration companies sought out silver deposits, set up mines to pull the silver out of the earth, and then shipped it to a refinery. Gold and copper and zinc and iron still get mined this way.

silver ore smelting - YouTube

May 17, 2016 · Smelting Silver Ore with the KK-6. How to identify raw silver and silver ore_(What silver bearing rock looks like) - Duration: 35:35. Chris Ralph, Professional Prospector 43,865 views

Silver Mines in Australia — Who’s Digging, and Where? | INN

Interestingly, the majority of the country’s silver is produced as a by-product at highly mechanized underground lead – zinc and/or copper mines. Refined silver comes mainly from the Port Pirie...