water injection for cement mill

water injection for cement mills powblachownia.pl. Jun 15 2018 · Normally water is injected in first chamber where the temperature of the clinker is on higher side ie above 100 degree C The water injection system is naturally provided with a regulator It starts when the temperature of the cement mill outlet exceeds a given value of 105 degree C If temperature is on lower side the water system ...

Cement mill - Wikipedia

A cement mill (or finish mill in ... This gives good cement performance, and reduces energy consumption by 20-40% compared with a standard ball mill system. Capacity of cement mills. The cement mills on a cement plant are usually sized for a clinker consumption considerably greater than the output of the plants kilns.

Estanda completes ball mill water injection system …

Estanda completes ball mill water injection system for Buzzi, Italy 27 November 2015 At the end of October 2015, Estanda completed the installation of a water injection system for a 3.8m diameter ball cement mill for the Buzzi Unicem group (Italy).

Cement ball mills without water injection - Page 1 …

9-11-2009 · Re: Cement ball mills without water injection. Dear mb14, As per my experience it is not possible. I have calculated by considering cement mill somewhere in -40 C climatic condition than also i can reduce only 25 % of present water consumption.

Water injection to the top cyclone - Page 1 of 1

Water injection to the top cyclone. Hi everyone, In our plant the top cyclone temperature is around 375 C. The dust recurculating is around 13% of the feed. Because of the build-up in the fun we are facing with unplanned shutdown every week.

Re: Cement ball mills without water injection - …

Re: Cement ball mills without water injection. Dear Mr. Lal, If you will go through my mail, I have mentioned the same thing. It is impossible to run the mill without water.( for cooling ) Vikpro . Reply. Know the answer to this question? Join the community and …

Grinding trends in the cement industry - Cement …

Summary: The main trends concerning grinding processes in the cement industry are still higher efficiency, reduction of the power consumption and system simplicity. In the case of new orders, vertical mills have increased their share to over 60 % and ball mills have fallen to less than 30 %. It is somewhat surprising that the number of different grinding processes and mill types used by the ...

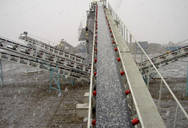

water spray in cement ball mill photo

water injection for cement mill . t;Cement mill and mill water injection system for cement plant miningbmwFL ball mill for cement grinding. Versatile system based on standard modules 2 The FL ball mill is designed for grinding of clinker, gypsum and dry or moist additives Cement Mill Water Injection snmarketingCement ball mills without water ...

Water injection system for ball cement mills - …

At the end of October 2015, Estanda completed the installation of a water injection system for a 3.8 m diameter ball cement mill for the Buzzi Unicem group (Italy). This project enabled us to achieve the target requested by the customer: to obtain an outlet temperature in the cement of lower than 100 °C without compromising the quality of cement and maintaining the productivity of the process.

Cement kiln - Wikipedia

Cement kilns are used for the pyroprocessing stage of manufacture of Portland and other types of hydraulic cement, in which calcium carbonate reacts with silica-bearing minerals to form a mixture of calcium silicates.Over a billion tonnes of cement are made per year, and cement kilns are the heart of this production process: their capacity usually defines the capacity of the cement plant.

central drive cement mills water spray system

central drive cement mills water spray system . ... further comprising a central drive shaft having a first end connected ... Cement Mill Water Spray System, ... Get Price; mill water injection system for cement plant. mill water injection system for cement plant, ... cement mill in central drive water spray. water injection for cement mills ...

How we control the temprature in cement mill

Water Injection System For Ball Cement Mills Fundiciones. ... Cement Mill Equipments Cement Mill Water Spray. Magnetic Separation Production Line of Changning Manganese Mine in Hunan Province. Cement Kiln Wikipedia. ... How To Control Residue In Ball Mill In Cement Plan.

Nozzle Lances and Systems for the Cement Industry

Nozzle Lances and Systems for the Cement Industry. 2 Company founded by Paul Lechler Patent for ... operation of downstream plant components. roller mill Injection of water to stabilize the grinding bed and to opti mize the grinding process. Ball mill Injected water lowers the temperature in

Water injection

The Art Of Sharing and...Imagination. Home; About Us; Services. Grinding Software; Consultancy; Training Courses; Calculators Online

Finish Mill Cement Plant | Crusher Mills, Cone …

Search cement finishes mill water spray systems to find your need. … cement finishing mill water spray; … mill water injection system for cement plant; roller mill of cement plant | …

FCB Horomill® - Fives in Cement | Minerals

The FCB Horomill ® is a breakthrough technology in bed compression grinding that enables producers to improve their grinding plant operation. In order to enhance the plants’ production capacity and optimize the plant maintenance, Fives has implemented significant technical development on …

Water injection system - WIS™ | Magotteaux

Optimize your grinding process via temperature control Water injection is one way to control and maintain the cement temperature at mill outlet at a preset level. Depending on the circuit thermal balance analysis and the mill design, Magotteaux water injection system (WIS™) automatically sprays water into the mills in 3 different ways: 1st chamber via its inlet 2nd chamber via mill outlet or ...

Ball Mills | Ammermann Pty Ltd

Ph: +61 2 4372 1234. Ammermann Pty Ltd. 1 Ainslie Close Somersby, NSW 2250.

Cement Directory: Mill Internals

Mill Internals. A R Engineering. ... Cementrade is a supplier of grinding media, lining for cement, raw mills and heat resistant casting. ... JHMC is an equipment supplier, specializing in power plant equipment, cement plant facilities,mining ... KCP Heavy Ltd. KHD Humboldt Wedag.

Cement Cooling System - Efficient, Industrial …

Cement High-efficiency cement cooling. The Solex heat exchanger is capable of handling any relatively free-flowing powder or crystalline bulk solids, making it the perfect candidate to cool cement, while using up to 90% less energy compared to direct cooling methods.