Bilder von gypsum manufacturing process

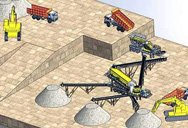

Gypsum production process. Gypsum ore, from quarries and underground mines, is crushed and stockpiled near a plant. Asneeded, the stockpiled ore is further crushed and screened to about 50 millimeters (2 inches) in diameter.

11.16 Gypsum Manufacturing - US EPA

To produce plasters or wallboard, gypsum must be partially dehydrated or calcined to produce calcium sulfate hemihydrate (CaSO4½H2O), commonly called stucco. A flow diagram for a typical gypsum process producing both crude and finished gypsum products is shown in Figure 11.16-1. In this process gypsum is crushed, dried, ground, and calcined.

Gypsum Board Manufacturing Process - YouTube

13.04.2018 · How to make gypsum board in a continuous process, let us see a trial demo.

Five stages of gypsum production process | Stone …

15.01.2012 · There are five basic stages in gypsum processing: Excavation is sometimes carried out by digging out an area of ground where the gypsum is located using open-cast techniques. To reach deeper deposits drift or shaft mines may be needed. The drilling and digging equipment is applied to dig out the gypsum ore in excavation stages.

the role of gypsum in cement production

gypsum production process . Gypsum and Cement Production two Schenck Process Gypsum is a mineral and is hydrated calcium sulfate in stone form Gypsum plays a very important role in controlling the rate of hardening of the cement During the cement manufacturing process upon the cooling of clinker a small amount of gypsum is introduced during the final grinding

Gypsum Board Production Business Plan Sample …

Gypsum and plaster of Paris are the principal raw materials of the unit. Apart from this, you will need to procure packaging consumables. Gypsum Board Manufacturing Process. The manufacturing process includes several steps. Step-1. Gypsum is Disc Pulverized after drying. Then calcine the item in Rotary Drum Calciner at 140°C to 170°C for about two hours.

Making Gypsum Board – Gypsum Association

To produce gypsum board, crushed natural gypsum or synthetic gypsum is is heated or calcined to dehydrate the feedstock. Next the calcined gypsum is mixed with water and additives to form a slurry which is fed between continuous layers of recycled stone on a long board machine.

Gypsum Processing

Material Processing Pelletizing Equipment. When it comes to agglomeration, FEECO’s expertise is second to none. In addition to complete pelletizing systems, we can provide you with individual, custom-engineered pieces of agglomeration equipment.. Our pin mixers and disc pelletizers are frequently used to process gypsum into a premium pellet product. Pin mixers are also ideal for use in de ...

Coronavirus (Covid-19) | British Gypsum

5th June 2020 – 10.00. We have now embedded the new Covid-19 safe operating procedures into our business, enabling the successful re-start and scaling up of our mining, manufacturing and logistics across the UK, to support the construction industry, provide protection for our customers’ and colleagues’ livelihoods, and play a vital part in the recovery of the UK economy.

Phosphogypsum - Wikipedia

Phosphogypsum refers to the calcium sulfate hydrate formed as a by-product of the production of fertilizer from phosphate rock.It is mainly composed of gypsum (CaSO 4 ·2H 2 O). Although gypsum is a widely used material in the construction industry, phosphogypsum is usually not used, but is stored indefinitely because of its weak radioactivity. ...

Gypsum Powder Production Line - YouTube

19.08.2016 · In the gypsum mill process, according to the customers investment,output scale and application object,we can choose among ramond mill,vertical mill to …

Gypsum and Cement Production - two ... - …

Gypsum and Cement Production - two elementary building materials. Cement is used everywhere imaginable: for example, as a binder for concrete, mortar or screed, making it one of the worlds most important building materials. If we just consider concrete, most of our infrastructure and architecture simply wouldnt be conceivable without it. And gypsum plays a similarly important role inside ...

BLM approves 100-acre expansion at Gypsum …

Vor 1 Tag · GYPSUM — U.S. economic conditions ultimately determine production decisions at the American Gypsum Company wallboard plant and mine in Gypsum, but as of right now, the operation is set for the next 60 years on the resource front. On Friday, the U.S. Bureau of Land Management announced it has approved a 100-acre expansion plan for the American Gypsum Company’s Eagle-Gypsum …

What is Gypsum Board? – Gypsum Association

Type X Gypsum Board – a gypsum board with special core additives to increase the natural fire resistance of regular gypsum board. Gypsum board is one of many gypsum panel products, defined in ASTM C11, Standard Terminology Relating to Gypsum and Related Building Materials and Systems , as “the general name for a family of sheet products consisting essentially of gypsum.”

Gypsum Plasterboard Manufacturing Process

GYPSUM TO GYPSUM FROM PRODUCTION TO RECYCLING. 2016-6-21demolition gypsum-based waste into the plasterboard manufacturing process up to a maximum target of 30 ww in feedstock is investigated and the resulting impact on variable plasterboard manufacturing costs is techno-economically assessed, based on data collected from pilot projects.

Production of commercial-grade gypsum | Power …

Many new FGD systems will be designed to produce calcium sulfate dihydrate (CaSO4•2H2O), also referred to as gypsum, as a byproduct. A frequent consideration is the well-established commercial...

Gypsum Product Manufacturing in the US - …

Gypsum Product Manufacturing in the US industry trends (2014-2019) Gypsum Product Manufacturing in the US industry outlook (2019-2024) poll Average industry growth 2019-2024 : x.x lock Purchase this report or a membership to unlock the average company profit margin for this industry.