Vertical Mill Internal Wear Parts - alanya-oba.de

Vertical Mill Internal Wear Parts. Milling Equipment: vertical mill internal wear parts - A class of machinery and equipment that can be used to meet the production requirements of coarse grinding, fine grinding and super fine grinding in the field of industrial grinding.The finished product can be controlled freely from 0 to 3000 mesh. We Are Here For Your Questions Anytime 24/7, Welcome Your ...

Vertical Mill Roller Wear Measurement - …

Hydraulic system vertical roller mill operation. Hydraulic system vertical roller mill operation 1. The working principle of the hydraulic system vertical roller mill The hydraulic system ofvertical mill is an important system, the main function ofthe hydraulic system is to break the grinding roller, which is when the internal grinding cavity wear parts wear, can stop open on both sidesofthe ...

Hydraulic system vertical roller mill operation

Hydraulic system vertical roller mill operation 1. The working principle of the hydraulic system vertical roller mill The hydraulic system ofvertical mill is an important system, the main function ofthe hydraulic system is to break the grinding roller, which is when the internal grinding cavity wear parts wear, can stop open on both sidesofthe grinding roller mill, to replace the inside parts ...

China Vertical Mill Parts, Vertical Mill Parts ...

China Vertical Mill Parts manufacturers - Select 2020 high quality Vertical Mill Parts products in best price from certified Chinese W Parts manufacturers, Other Parts suppliers, wholesalers and factory on Made-in-China.com

Grinding Mills: Ball Mill & Rod Mill Design & Parts

Common types of grinding mills include Ball Mills and Rod Mills. This includes all rotating mills with heavy grinding media loads. This article focuses on ball and rod mills excluding SAG and AG mills. Although their concepts are very similar, they are not discussed here. Photographs of a glass ended laboratory ball mill show action of ball mass within the mill. The action of other grinding ...

coal vertical mill wear parts - hausbau-handwerk.de

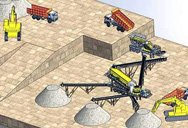

Wear Services, Inc. Parts Of Vertical Coal Mill Of Power Plant. We are a large-scale manufacturer specializing in producing various mining machines including different types of sand and gravel equipment, milling equipment, mineral processing equipment and building materials equipment.

Tables | Magotteaux

Expect the highest mill availability! Mostly supplied in segmented parts, occasionally as monobloc casting, the grinding table receives the material grinding bed submitted to the tires pressure as per the vertical mill working principle. Hence those parts need outstanding wear resistance. Magotteaux offers a vast choice of alloys with or without ceramic grains (MMC – Metal Matrix Composite ...

Vertical Mill,Vertical roller mill,Vertical powder mill ...

HRM LM ZGM vertical roller mill wear parts Widely used in metallurgy, electric power, cement, chemical, ceramics, non-metallic minerals, power p; ball mill 30-250 mesh grinding, 0.5-100 t/h; Raymond Vertical Mill output size: 30-425 mesh, 1-30 t/h; large vertical grinding mill output size: 30-1000 mesh, 10-400 t/h; Vertical Roller Mill for Cement, Clinker, Slag, Clirik vertical roller mill for ...

Lining Plate Of Vertical Mill Price And For Sale

LM Vertical Mill - Crusher Spare Parts For Sale. Wear Parts Of LM Vertical Mill. Roller sleeve. Roller sleeves are installed on rollers, wrapped around the roller. Lining plate. Lining plates are installed around the grinding chamber. READ MORE

Maintenance of wear parts for a ball mill and …

For a ball mill grinding OPC to a fineness of 3200 to 3600 cm 2 /g (Blaine) the cost of wear parts (ball, liners and mill internals) is typically 0.15-0.20 EUR per ton of cement. For an chaeng vertical mill grinding a similar product, the cost of wear parts depends on the maintenance procedures, i.e. whether hardfacing is applied.

KREBS® millMAX™ Slurry Pumps - FLSmidth

The key advantages of our efficient millMAX Slurry Pump design are lower power requirements (up to 30% less); long, even wear life; and less pump downtime – all of which result in lower cost-per-ton pumped along with better cyclone separation.

Vertical Roller Mill Wear Parts

vertical Roller Mill Wear Parts such as tires, grinding ring segments, armor rings and spindle shields are cast from our high chromium alloy irons and fully heat treated for optimum mechanical properties. Tires and grinding ring segments are also accurately machined to tight tolerances for precise fit.

vertical roller carbide - redhatsocietyeindhoven.nl

Maintenance And Repair Of Vertical Roller Mills An. Maintenance Of Vertical Roller Mill 1 routine inspection routine inspection and maintenance of the vertical grinding mill may avoid unplanned downtime of the equipment due to improper lubrication regular inspection allow wear parts can be replaced in time to ensure the normal operation of equipment 2 normal check (1)daily check an …

Wear Parts for Vertical Mills - nepcast.com

Wear Parts for Vertical Mills. Products. Services. Circular Economy. Contact Us. SAG Mill Chutes. Wear Parts for Vertical Mill. Ball Mill Components. Components for Slurry Tranportation. Wear Resistant Components. Spares for Slurry Pumps. ELEMENTOS DE DESGASTE FUNDIDOS. Piping and Duct Manufacturing with stone Inner Lining.

Vertical Mill Rocker Arms Manufacturer From China …

The vertical mill rocker produced by SYMMEN METAL Casting has better wear-resistant capability and good anti-cracking. We carry out the dressing and finishing by arc air gouging and shot-blasting for the steel castings to guarantee the appearance quality.

Replacement Wear Parts | Schutte Hammermill

Replacement wear parts for hammer mills and shredders, including hammers, screens, discs and cutter teeth, wear plates, bearings and more. Request A Quote 1-800-447-4634

Vertical Roller Mill Wear Parts - Gravel Mill

vertical roller mill has many wear parts. These wear parts include grinding roller, grinding millstone, classifier vane and other wear parts. This article will introduce the vertical roller mill wear parts from the function and texture of material.

Wheel Hub Manufacturer From China - Symmen …

The vertical roller mill wheel hub of grinding roller produced by SYMMEN METAL Casting has good wear-resistance, and are hard to break. Cement & Mining Parts Machining Product

Hardfacing for of Wear Part for vertical Roller mills …

26-3-2016 · Hardfacing for of Wear Part for vertical Roller mills by Hardcored Technology BCC ... Hardfacing for Vertical Rollers Mills Parts ... Hardfacing, Wear Plate, Wear Parts 31,765 views. 3:36.

Windmill - Wikipedia

A windmill is a structure that converts wind power into rotational energy by means of vanes called sails or blades, specifically to mill stone (), but the term is also extended to windpumps, wind turbines and other applications. Windmills were used throughout the high medieval and early modern periods; the horizontal or panemone windmill first appeared in Greater Iran during the 9th century ...