Stirred mills - for wet grinding - liming

The stirred milling technologies can be divided into two sub-categories: gravity-induced stirred mills and fluidized stirred mills. Gravity-induced stirred mills initiate a ball charge motion via rotational movement of a screw to provide a size reduction mechanism.

Stirred mills for milling & grinding | FLSmidth

Stirred mills & Tower mills — simple, effective and cost efficient As lower ore grades and complex mineralogy are driving demand for more efficient fine grinding, you can depend on FLSmidth for a full range of fine-grinding mills designed for easy shipment, simple erection and trouble-free maintenance.

Stirred media mills in the mining industry: Material ...

This review describes stirred media mill technologies and operating principles, and summarises stress intensity theory which can be used for selecting efficient operating conditions. For fine and ultrafine grinding, the Bond work index is an inappropriate measure of grindability, so alternatives are discussed.

Stirred Milling Technology – A New Concept in Fine Grinding

Unlike tumbling mills, where comminution occurs from both impact and attrition grinding, in stirred media mills the particles suffer almost entirely attrition breakage between the beads. (Napier-Munn et al., 2005). In stirred mills there are no free-falling possibilities for …

Metallurgist & Mineral Processing Engineer

Metallurgist & Mineral Processing Engineer

Discrete particle simulation of particle flow in a stirred ...

The results suggest that selection of stirrer geometry also depends on the feed size and the type of material to be ground. Discussion has also been made of the usefulness of particle scale information in the design and control of stirred mills of different types. Original language: English: Pages (from-to) 1050 - 1061: Number of pages: 12 ...

(PDF) Vertical stirred mill scale-up and simulation: Model ...

Stirred mills can be divided into two classes: those with low agitator speeds, that also use gravity to promote media movement and apply forces, and those with high agitator speeds, with the speed...

Towards a Better Understanding of Stirred Milling ...

stirred mills spanning a number of industries that require fine and ultrafine grinding. In the context of the mining industry, smaller stone size and other mineralogical characteristics have motivated the need to grind finer. In order to address this need, the interest in stirred milling ...

AMIT 135: Lesson 6 Grinding Circuit – Mining Mill Operator ...

Basic Mill Linings. Use stone linings wherever possible due to lifetime, low weight, easy to install and noise dampening.; When application is getting tougher use steel-capped rubber, still easier to handle than steel.; When these both options are overruled (by temperature, feed size or chemicals) use steel.; Ore-bed is a lining with stone covered permanent magnets used for special ...

Improving The Efficiency Of Fine Grinding – Developments ...

The modern high intensity stirred mills (such as the IsaMill) further extend the energy benefits of this technology by using higher agitation speeds and smaller media particles. Media selection has a major influence on mill parameters such as energy efficiency, internal wear and operating costs.

METHODOLOGY TO PREDICT PRODUCT SIZE DISTRIBUTION …

stirred grinding mill using the population balance model. Initially, detailed experimentation was carried out in a Bond Ball Mill and the breakage and selection functions were determined for the aggregate material tested. After collection of the breakage parameters, it was possible to predict the product size distribution as a function of grinding time.

Stirred Milling machine development and application extension

liming stirred mills Product role The VERTIMILL® and SMD applied correctly can provide improved grinding efficiency, reduced media consumption, and lower installation and operating costs when applied in the right application. There appears to be significant overlap with ball mills 17 13 Nov 2013 1 m 100 mm 10 mm 1 mm 100 micron 10 micron 1 micron

ATTRITORS AND BALL MILLS HOW THEY WORK Robert E. …

IV. BALL MILLS Ball mills are one of the more common mills and use a closed cylindrical container that is rotated horizontally on its axis so that the media cascades. A typical ball mill has an L/D ratio of 1.5:1. Ball mills are filled with spheres or other shapes made of steel or ceramics; or with pebbles made of flint (or of an ore being ground).

Nanomilling of Drugs for Bioavailability Enhancement: A ...

May 20, 2016 · The selection of optimal stabilizer formulation is a laborious and resource-demanding task, yet an important one with potentially serious consequences. ... Among the wet media milling processes which use various equipment such as stirred mills, planetary mills, ball mills, etc., the wet stirred media ... and the use of vertical stirred mills ...

Predicting the product particle size distribution from a ...

The use of ball mills for fine grinding is inefficient and has contributed to the increasing popularity of vertical stirred mills in the mineral processing industry.

circular type stirred mill - Mine Equipments

stirred ball mill was issued. Using The Product Selector | Fairford Electronics A ball mill is a type of grinder used to grind materials into extremely fine powder for... by crushing it like a jaw or spinning it in a circular motion at high speeds. A New Approach in Exciton-Coupled Circular...

wet grinding stirred media mills solution for ore mining

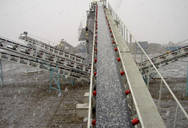

Stirred mills for wet grinding liming. Stirred mills are used for wet grinding. Ideal for grinding finer products, stirred mills are known for operational efficiency and smaller required floor space. liming offers both gravity-induced and fluidized technologies in Vertimill® and Stirred Media Detritors (SMD), allowing for the optimum equipment solution for your circuit.

stirred mill grinding - klimaatwebsite.be

The IsaMill (high capacity horizontal stirred mill) is referred to as an enabling technology Through significantly lowering the cost of fine grinding, many locations that had high grade but fine grained ore became economical Stirred mill technology energy efficiency is extremely dependent upon several variables including grinding media selection

stirred and vibratory mills - redhatsocietyeindhoven.nl

continuous vibratory mill for microgrinding ball mill. Vibratory grinding mills have been around for some time but the VKE mill is a unique and major development in vibratory fine grinding utilizing a tuned spring system to completely suspend the grinding chamber and the vibratory motor energy design saves and reuses the rebound energy and permits the construction of a lowcost and ...